Let’s talk about Laser & Ozone techniques.

The processing of jeans is complex which is why we have put together a short series where we are going to give you a breakdown of how our jeans are made and explain some of the sustainability related credentials.

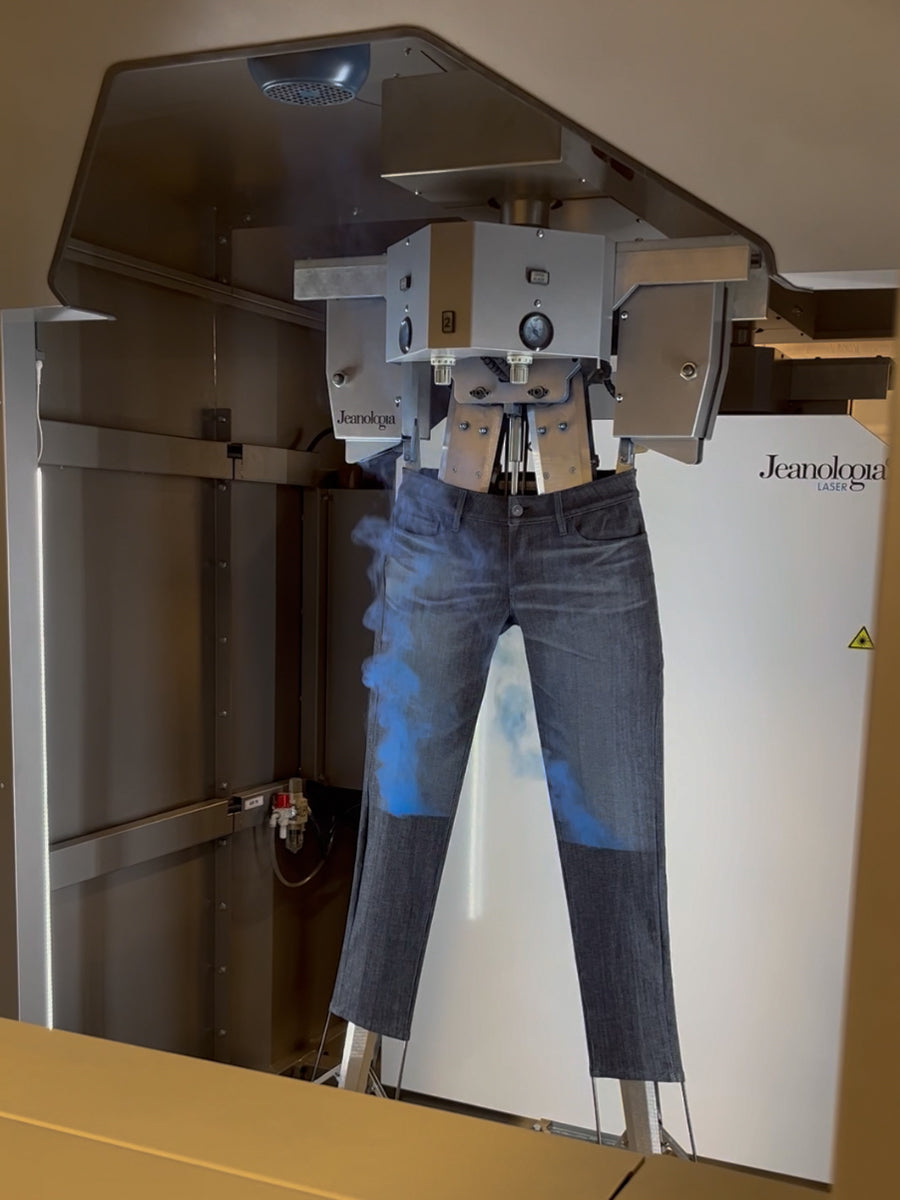

Firstly, let’s talk about Laser & Ozone techniques. We are starting with this because we are launching our new Dandelion jean which features a laser design that you can see here.

This pattern has been created by using laser technology in the form of a plant shape. What makes this jean extremely innovative is that other brands achieve patterns on their jeans by using harmful chemicals and bleaches but what a laser does is eliminates the use of these chemicals.

Not just that Laser & Ozone techniques are used to create the fabric. Our jeans have gone through eco-friendly washes instead of hazardous methods to achieve the colour in the first place.

Normal manufactures put the jeans through a stone wash that can use 70 ltrs for just one pair of jeans.

With laser treatment no water or chemicals such as beach are used but rather laser technology with less impact on the environment, finishing off the denim process with fewer steps.

Additionally, the jeans have been through finishing technique which saves steps in the production process reducing water, chemical products energy & time.

All that to facilitate the industrial garment washing process (less water, energy, chemicals, time) and getting a good looking final product.

Shop your Dandelion Jean here.

Stay updated about more upcoming community events by subscribing to our weekly newsletter. P.S. You'll receive 10% off your first order as a thank you!